MARINESHELF publishes articles contributed by seafarers and other marine related sites solely for the benefit of seafarers .All copyright materials are owned by its respective authors or publishers.

There are 3 systems of airflow scavenging in common use

for Two Stroke Engines.

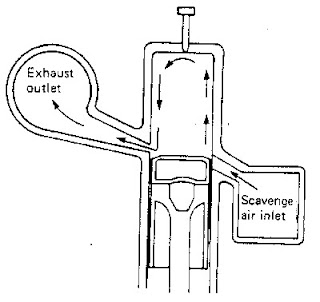

Exhaust and inlet ports are arranged around the periphery of

the lower end of the liner opposite to each other and in so doing eliminate the

necessity for cylinder head valves and their operating gear. This considerably simplifies engine

construction and can lead to reduction in maintenance. As shown in the figure

above there is usually a deflector-head type of piston, the object being to

avoid short-circuiting by directing the airflow. This deflector head is troublesome from heat

flow considerations; because of the metal thickness required and the difficulty

in cooling it. Combustion space is not thermodynamically best for oil

engines. An alternative construction is

the angling of the inlet ports towards the top of the cylinder to direct the

airflow. This method is not so effective

and it increases cylinder liner costs.

Usually, top edges of exhaust ports are higher than those of

scavenge ports. Cross scavenging systems may not be very effective and the b.

m. e. p. may not usually exceed 3 to 3.5 bar, but their simplicity and low cost

may often be more important than high specific output. This system was popular

in early days before turbo-charger introduction, to keep weight of engine

balanced on either side, by scavenge and exhaust trunkings. When turbo-chargers

were introduced both these trunkings has to be on one side to facilitate

connections. Old type Sulzer (RD) Engines used this system.

1 comment:

Nice information! The superiority of knowledge intimidates me. Buy good quality Pumps from authorized suppliers, There are several high-quality Pumps available here. To learn more about what I know, please click here TFTpumps.com

Post a Comment