MARINESHELF publishes articles contributed by seafarers and other marine related sites solely for the benefit of seafarers .All copyright materials are owned by its respective authors or publishers.

Combustion.

This is an exothermic reaction (one in which heat is

liberated by the action) between a fuel and oxygen. Liquid fuels consist of

carbon, & hydrogen, in the form of hydrocarbons, with small quantities of

sulphur & traces of other metallic Impurities such as vanadium.

A typical fuel analysis, by mass would be:

C = 5%, H2 = 12%, S = 3%, with a C.V. of 44000

KJ/Kg.

(19000 BTU/lb.)

The oxygen is obtained from the air, which can be considered

to contain 77% nitrogen & 23% oxygen by mass.

The nitrogen plays no active part in the combustion process

but it is necessary as it acts as a moderator. With pure oxygen, the combustion

would be violent & difficult to control & it would produce very high

temperatures, creating cooling, metallurgical & lubrication problems.

The reactions, which occur, are:

2H2 + O2 ----------- 2H2O –

liberating 142 MJ/kg. H2.

C + O2 -------------- CO2 – liberating

33 MJ/kg. C.

S + O2 --------------- SO2 –

liberating 9.25 MJ/kg. S.

2C + O2 --------------2CO – liberating 10 MJ/kg.

C.

Combustion will only occur within limits in the air/fuel

mixture. If too much air is supplied all the fuel will be burnt but the excess

of oxygen & nitrogen will carry away heat. If too little air is supplied

incomplete combustion will occur, when all the hydrogen will be burnt but only

part of the carbon, with the remainder only burning to carbon monoxide or not

burning at all. In diesel engine practice it is usual to supply between 100

& 200% excess air by mass, though 15% is sufficient for a steady flow

combustion process (boiler).

This difference has two reasons:

- As the

combustion proceeds in the diesel engine, the fuel finds less & less

air to combine with in a boiler air is constantly being fed in.

- More

air is needed in the diesel engine as it lowers the maximum temperature,

allowing Cast iron to be used.

Combustion Process.

Fuel is injected into the clearance volume towards the end

of the compression stroke, as a fine mist of very small droplets, which have a

surface area many times that of the accumulated fuel charge. These droplets are

rapidly heated by the hot compressed air, which has a temperature of between

550* to 650*C, causing vaporisation. The vapour mixes with air and when the

mixture exceeds the spontaneous ignition temperature, (S.I.T.) combustion

begins.

The process can be divided into four phases :

Injection delay:

A time lag of about 0.005 seconds occurs between trapping

the fuel charge in the pump barrel and starting injection into the engine

cylinder. This is due to:

a) Elasticity

of high-pressure fuel lines & system.

b) Slight

compressibility of the fuel charge.

c) Leakage

past the pump plunger & injector needle.

d) Opening

delay of the pump discharge valve & injector needle.

In a slow speed engine the lag period accounts for up to 5*

of crank movement. In a high speed engine it may account for 20* or more and

because of point (a) it is necessary to use fuel lines of similar length for

all cylinders, when the fuel pumps are grouped together.

Ignition Delay.

Ignition delay is another short period of time delay, which

is sufficient to account for several degrees of crank angle. Several factors

are involved:

a) Spreading

and penetrating of the fuel in to the clearance volume space.

b) Heating

of the fuel to cause vaporization & then exceeding the fuels’ spontaneous

ignition temperature.

c) Mixing

of the fuel & air in the clearance volume space before detonation.

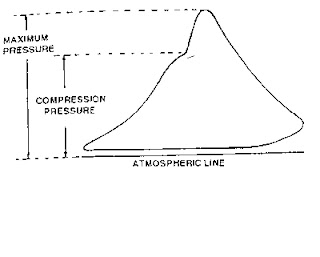

Constant Volume Combustion.

Ignition occurs at T.D.C. when the fuel charge, which has

entered during the ignition delay period, burns rapidly causing a sharp rise in

cylinder pressure with little movement of the piston occurring. Modern four

stroke engines may attain 100 bar; at this point where as a two stroke engines

are likely to operate with pressures of 75 to 98 bar.

Direct Burning.

The remainder of the fuel burns as it enters the cylinder

and mixes with air. The excess air and combustion gases prevent high

temperatures and rapid combustion so the pressure remains about constant.

Injection and combustion should cease simultaneously at the end of this period.

Factors Affecting Combustion.

In order to attain good combustion it is essential that:

a) Sufficient

air is supplied.

b) Compression

is high enough to give a temperature above the spontaneous ignition

temperature.

c) Good

mixing of the air and fuel is obtained.

All of these give problems. The factors affecting

combustion are:

1. Atomisation.

2. Penetration.

3. Turbulence.

1. Atomisation.

The rate of heat absorption and burning depends upon the

surface area of the fuel particles. As this must be rapid it follows that the

surface area needs to be big & this is achieved by breaking up the fuel

into small droplets. The amount of the fuel pressure, diameter of injector

nozzle holes and the viscosity of the fuel, affect the process.

2. Penetration.

To use all the air in the combustion space it is necessary

to give the fuel particles sufficient energy to enable them to penetrate to the

extremes of the space. This is controlled by the fuel pressure, the size of the

particle & the length to diameter ratio of the nozzle hole (From 2:1 to

5:1). The latter also controls the angle of spray.

3. Turbulence.

To aid mixing of fuel with air and atomisation, friction

between the fuel & air is needed. Friction is a function of the relative

velocity between the fuel particle and the air, and may be obtained by either

of two methods.

a) Fuel

seeks air.

b) Air

seeks fuel.

a) The

air is static or slow moving and the mixing energy is obtained from the fuel

particles. Injection pressures of 200 to around 1000 bars are needed from

multi-holed nozzle injectors. Advantages are, simplicity, economy and easier

for cold starting the engine. The latter because little air movement means

reduced heat loss to the cold liner and piston crown (also assists in the

burning of heavy fuel). Disadvantages are in producing and sealing high fuel

pressures.

b) The

air is made to swirl rapidly at the end of the compression stroke by using a

pre-designed combustion chamber. Single holed nozzles and lower fuel pressures

are used, 70-100 bars. Advantages are simplicity of injection, equipment and

rapid combustion (useful in high speed engines). Disadvantages are complicated

combustion chambers and high rate of heat loss to surroundings. Causes

difficulties in cold starting, sometimes needing cylinder combustion space

heating system.

In practice, a combination is often used minimum fuel

pressures being used with a small degree of swill produced by vaned inlet

valves or tangentially cut scavenge ports.

Quantity of swirl causes half the liner circumference to be traversed

during combustion.

Combustion Faults.

Detonation.

The combustion process is regarded as a controlled explosion

with a flame front speed of about 25 m/s. However if combustion conditions are

not correct double ignition may occur and a ‘detonation’ may result. The latter

occurs when the mixture is rapidly compressed by an initial ignition and the

remaining mixture is overheated and burns almost instantaneously (Flame speed

2000 m/s). The detonation can set up very high pressures, temperatures and

causes vibration of the cylinder and piston. It also reduces the efficiency of

the engine as energy is absorbed producing the vibration.

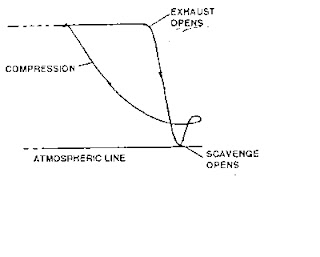

After burning.

This occurs when combustion extends into the expansion

period after the injector has closed. It is caused by poor ignition qualities

or very poor atomization and produces high exhaust pressures and temperatures.

Injection timing.

Early injection produces high firing pressures; late

injection produces low firing pressures and high exhaust pressures. In both

cases the engine power is reduced.

All these faults could be seen very clearly in indicator

cards of each unit.

Ideal Combustion.

To obtain maximum thermal efficiency, the combustion process

should be carried out as close to the Otto cycle as practically possible. This

means, the rate of rise of pressure should be as rapid as possible, without

exceeding the designed mechanical and thermal loading. To achieve maximum mean

effective pressure the fuel remaining after the initial period of rapid rise,

should be burned at a rate which will hold the cylinder pressure constant, at

the maximum design value until the fuel is burned.

Some of those factors affecting the ideal combustion can be

considered as follows.

Injection timing.

Using jerk injection system, it has been found that the

shortest delay period occurs when it includes T.D.C.

1. Early

injection results in increased delay since the pressure and temperature are

still rising, so auto injection energy has not been reached.

2. Late

injection causes increased delay since the piston is accelerating away from the

cylinder head and temperature and pressure fall rapidly.

In each case, the rate of pressure rise is increased due to

the large quantity of the fuel in the combustion space before the chemical

reaction is initiated. The reaction, which follows involves a massive amount of

fuel and approximates to detonation.

This results in ‘Diesel knock’, the effects of which are

determined objectionable. Many engines are timed later than that which gives maximum

mean effective pressure to reduce the rate of pressure rise and the maximum

pressure. This however involves some sacrifice in efficiency and power output.

Engine R.P.M.

Since the delay period is determined mainly by the fuel

characteristics, it follows that delay tends to be independent of engine speed.

The delay angle however will vary with engine speed and have considerable

influence on the pressure / crank angle diagram.

In each case – 10 deg. BTDC & 20deg. BTDC the delay

angle is increased with increase in speed.